Read this article by our ambassador Cristina Baghiu:

For several years now, I’ve embarked on a mission. Whenever I talk about it, I get mixed feedback depending to whom I’m speaking to.

I’m a strong believer that the future is technology-led. And I want to be an active part of it, as I want my family, friends, and community. That’s why my work is designed around human-centric digital transformation, or in plain words, how to use technology and workplace innovation for making our lives better.

Well, when I speak about technology adoption, it is a matter of “Yes, but…”.

Manufacturing SME owners would usually say that technology is vital for their company’s survival and future competitivity, but they lack access to funding or knowledge to implement it.

Technology providers would usually say that they need to educate the market first, as they must perform technology-push to make users aware of its benefits before selling and implementing it.

The HR manager struggling to source engaged candidates for an industrial sector that is providing mostly anything we need for our daily living would say it is a struggle almost lost from start, as they can’t find technology trained employees to stay longer than a couple of months, as they don’t pay as much as big corporates do.

Academia professors from the technical universities I work with, would usually say that they try to make an as accurate as possible competence and Industry 4.0 trends map for their study programs curricula, to make it relevant for industry and students alike, but technology trends have a stellar speed compared to academic programs pathway to delivery.

Take any SME manufacturing employee and they would say that, before introducing technology in their workplace, there are other things that should be solved there. And they would speak about one day about them…

Digital Twin – a solution for big and small businesses

Luckily, I come from a perspective that is both technology-agnostic and holistic. I don’t believe that a specific technology would have a better impact than other, or put differently, any technology will bring you one step further if you know what and when to use. And as a co-founder and coordinator of a European Digital Innovation Hub that is working with manufacturers and tech providers, in Europe’s one of least developed regions in terms of digital maturity, I strongly believe that we need entities (DIHs) to act as system integrators that will help us change those “Yes, but” in “Yes, Yes!!” affirmations.

Take the Digital Twin – it is an advanced digitalisation trend with a plethora of applications cross-industry, from manufacturing to healthcare, and not only a specific technology. I was very happy to discover the Change2Twin project and consortium and their essential work to support manufacturing SMEs in their digitalization process by providing Digital Twin solutions.

Barriers for digital twins? This is how to overcome them!

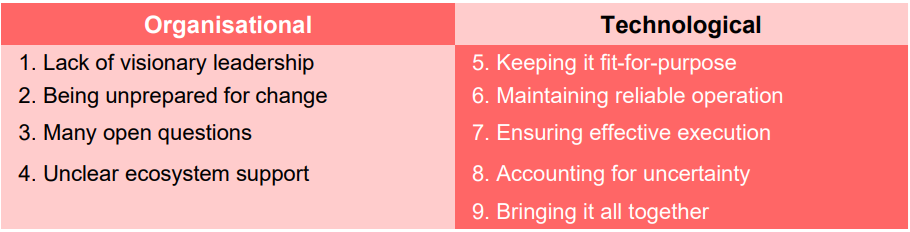

One of their latest position papers published brought more clarity to what we need to work with when introducing digital twins to manufacturing SMEs. There are 9 barriers that can easily be applied to other digitalisation trends as well:

I would always start with the WHY – identifying that visionary leader within the SME that understands where they want to go as an organisation for the next 5 years at least. In the past, the most successful projects I ran started with a vision & mission session, where everything is discussed out in the open by the management team, from forming an ecosystem, and knowing which partners need to be involved, to sharing research and industry trends.

The second barrier is critical to implementation, since digital transformation of the SME and their partners leads to new ways of working and new business models. Unpreparedness for change means to work in silos, use unfit workplace practices, lack of inter-departmental alignment or lack of agility of HR processes.

As an enabler of digitisation, Digital Twin enables new means and mechanisms that lead to innovation not only in technology, but also in new and alternative business models. This leads to open questions, that, ineffectively addressed, block the adoption of a digital transformation model. From whom is in charge to data security and IP challenges, all these questions need to be addressed from the start, preferably with the support of a third party, such as a Digital Innovation Hub, who doesn’t have a commercial purpose but a business support one.

The previous barrier leads us to another question: is this all the support I can get, as an SME, for Digital Twin implementation? A lack of an accepted basic definition and common language, standards, and best practices in industry, also results in a technological challenge. Requirements are hard to identify and address while different terms and ambiguous solution definitions are plentiful. By addressing this organisational challenge, we enable more focussed technology. Fortunately, there are projects, like Change2Twin, that developed a marketplace for models, tools and even a path to monetisation of the Digital Twin, once implemented.

But what is a digital twin model?

It is a combination of:

– data, giving insight into past, present, and future status of the system,

– system (model) knowledge, giving a view of aspects of the system as best we know it to be, and

– purpose-related models or algorithms that use the data and system knowledge (model) to calculate some fact about the system.

If any or all these derails from the initial purpose of implementing a technology that supports or enhances a business goal, we have a problem. A Digital Twin is as smart as the data we feed it with, and we need to be able to check the fitness of the model to improve it continuously. To make it operational, you need to be sure to onboard experts, not only in technology, but also understanding of your specific business challenges.

Digital Twin lifecycle – from cradle to grave

Lifecycle management of a Digital Twin is an important challenge to address because it is a complicated software and hardware system to manage. It combines lifecycle information, measurements of the asset state and simulations. They must be maintained by lifecycle management technology to reflect the actual state of a system. This includes new processes, like cognition, which naturally leads to self-awareness to support efficiency and validity. You invest in such a solution to be able to benefit from its prediction and life-like behaviour of the real-life twin, preferably for a long period of time. Otherwise, it will soon become obsolete or require complex retrofitting to make it work.

Now to the techy geeky stuff: effective execution. A sufficiently comprehensive Digital Twin will require substantial computational resources likely to be distributed over a cloud that combines private and public clouds with vendor platforms and HPC resources. What to do on edge versus what to do on cloud and what resources are available for optimum system architectures must be decided by experts, using design patterns, a security-by-design solution or distributed architectures. I cannot stress enough: you need experts for the implementation, and Change2Twin marketplace is an excellent place to start looking for them.

Next, it comes to the matter of trust and risk management. System engineering and operating methodology, like that of Model-Based System Engineering, are to be adapted to be able to maintain continued confidence and trust that the Digital Twin is performing as expected and will continue to do so in the system context it finds itself operating. Being able to identify who did what, when it was done, and why, gives the user of the results a means of accountability and allows avoiding worn decisions.

From where I stand, the Digital Twin is not a technology easy to understand. It is even more difficult to implement. Development of a Digital Twin requires understanding the dynamics of the system. These are presented in the form of requirements that the Digital Twin software must support. I believe that only an expert team of business and technology specialist can create a successful solution. You need to understand the data model, version the input of data models, or human interaction, talk in depth to the people that will use it. Seldom you are redesigning your entire factory. Probably the Digital Twin will service essential parts of your business and will have to communicate effectively with the rest, without interrupting existing processes and technologies.

How to transform these challenges into opportunities? How to make the impossible possible?

There is no recipe, but my recommendation is to:

- Measure what matters; assess & document where you stand, from business & technology perspective. Do it first as a honest self-assessment (even as a group exercise with your team), than talk it through with external experts. DIHs have a certified process for Digital Twin assessment that can bring extra clarity of the purpose and application recipes of the technology in your specific case

- Get experts on board. The marketplace provides a set of offerings that support the transformation towards a Digital Twin, from consulting to information, software or infrastructure offering

- Secure financing, either using a cost-saving approach to cover it from your budget, or via several grants for manufacturing business available in 2022 and 2023, that might be secured in your region, country or EU level. A good starting point is again the DIH in your region.

- Develop a human-centric approach to technology adoption. Technology is here to help us live better more sustainable lives and create better more sustainable products and services that will improve lives and create value for the community, our employees, our customers and, finally, for the company shareholders.

Follow me for more human-centric technology adoption perspectives.

Contact me for support and advice on technology adoption and digital workplace practices, the agile for people way.

Article by Change2Twin Ambassador Cristina Baghiu