Remoin Montajes is one of our beneficiaries from the last digital twin deployment call. They are now in the final stage of creating the digital twin, so we would like to introduce them to you.

Who is Remoin Montajes?

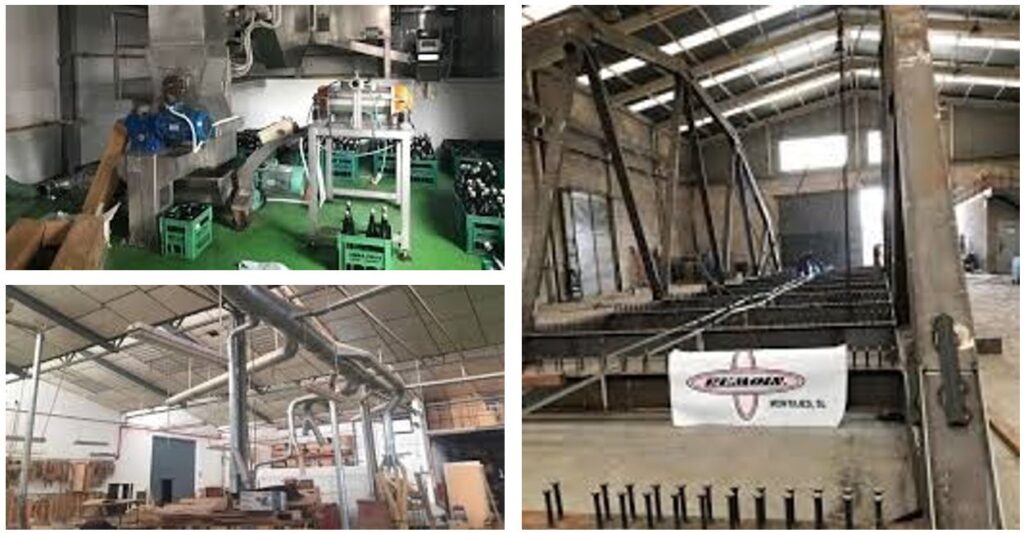

Remoin Montajes S.L. is a small manufacturing company located in Asturias (Spain), with 37 employees. It specializes in designing and constructing machinery, particularly for the food and beverage sector.

What is the purpose of their digital twin?

Our clients are small local cider producers who have have recently received IFS Food standard, which is a strict inspection of bottles. Cider is a traditional beverage in Asturias, still produced by artisan methods and bottles are reused by washing. Often they have no resources for automatic washing machine with laser detection and isteady still rely on human eye control, which is prone to error and contamination. Therefore, artisan cider producers often encounter a big dilemma how to comply with IFS Food standards while reusing the bottles and keeping them absoltely clean to prevent contamination.

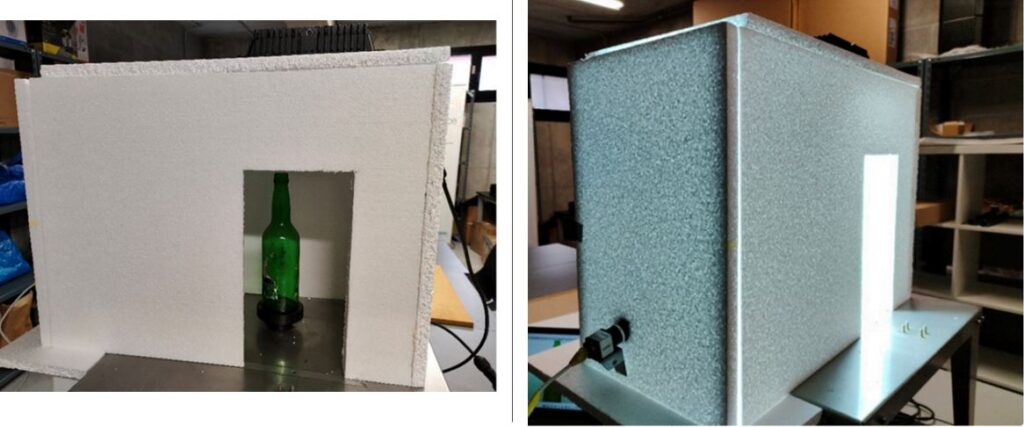

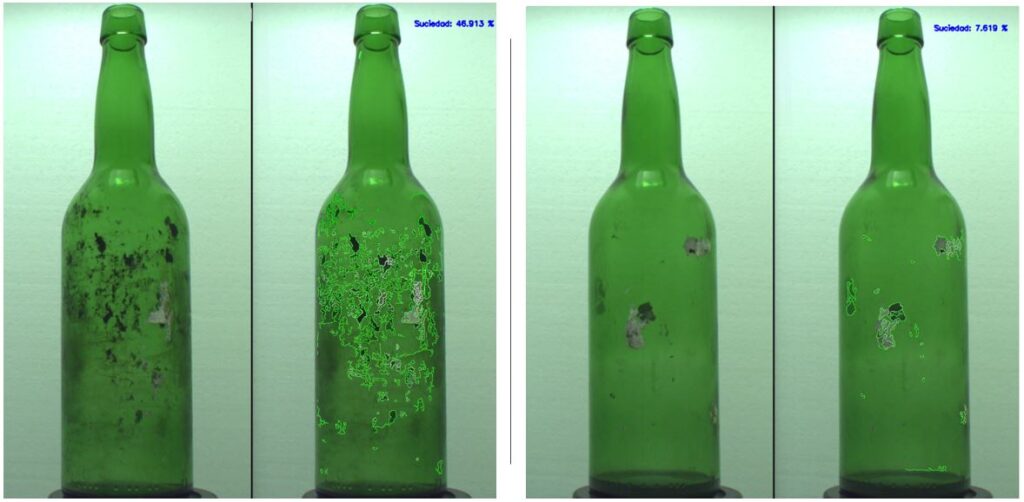

The purpose of the digital twin is developing a machine to automate the quality control of a cider bottle production line. The aim is to implement a system capable of ensuring the rigorous cleaning and disinfection conditions necessary when working with recycled bottles. Thanks to the implementation of a sophisticated dirt detection system based on artificial vision, better results are obtained by eliminating human error, thus adding value to the production process. Additionally, the objective is to design and implement a comprehensive system that includes a 3D simulation, the previously mentioned dirt detection software, and real-time control and visualization software for results and alarms.

Has the digital twin fullfilled their expectations?

The expectations from Remoin were exceeded. From the very beginning, research was conducted into the best technology for this project. Thanks to the implementation of the latest techniques in artificial vision, the objective of developing a dirt detection system was achieved.

This project also brought several improvements to the company. The need to develop a really sophisticated system compelled the company to research and work on the most cutting-edge technologies in artificial intelligence and computer vision, thus adding great value to the company. Furthermore, the involvement of two companies in the project fosters synergy and a way of working where communication and organization must prevail.

What are their future plans with the digital twin?

There are some lines and areas for improvement regarding the future of the digital twin, some of which include:

- Improving the accuracy of the dirt detection system. Due to the technologies utilized, the system’s accuracy increases with more data. Data acquisition occurs when the machine is operational, analyzing the bottles on the production line.

- Optimizing machine performance. Conducting thorough testing and performance analysis to identify potential bottlenecks in the production line and improve process efficiency and speed.

- Expanding the functionality of the digital twin. Considering the addition of new features to the digital twin, such as the ability to predict machine failures or simulate different production scenarios to optimize planning and logistics.

- Integrating advanced data analytics: Developing more advanced data analysis capabilities to extract valuable insights from the data collected during the production process, which could include trend identification, anomaly detection, or production parameter optimization.

- Study to incorporate the system for another type of food container. It could be investigated the possibility of developing the system for detecting other types of containers within the food industry.

Conculsion

“With the innovative approach of the digital twin of the cleaning and quality control of bottles, we will position ourselves as the sole company in our sector and geographic area that can fulfill the needs of the SMEs of the beverage sector in terms of quality and food safety, without investing high amounts of money. We are already planning to expand and adapt the concept to the control quality of other machines.” Olaya Munoz, technology consultant, UpIntelligence